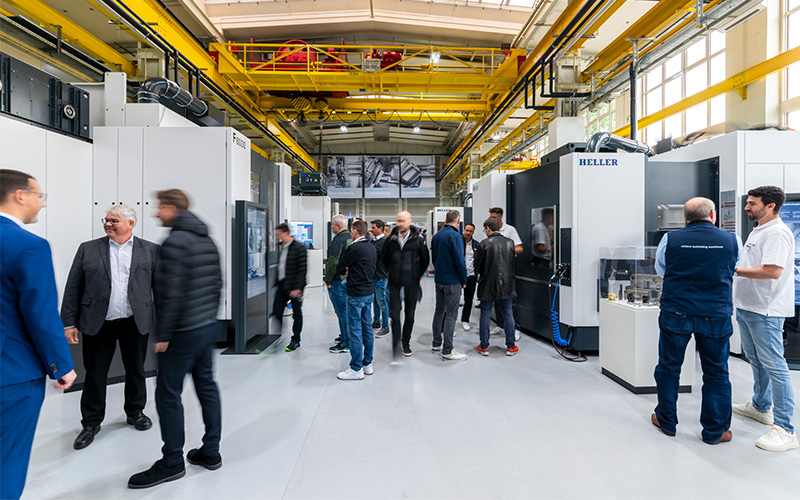

At the heart of HELLER’s presentation at EMO in Hanover will be 360° Performance – a holistic view of the demands placed on modern production. To meet these demands, HELLER focuses on five solution areas. In addition to the F 6000 5-axis machining centre from the latest generation of the F series, HELLER will be presenting products for the digitalisation and automation of production, a comprehensive range of services as well as innovative manufacturing processes and technologies for complete machining on a single machine.

HELLER’s commitment is to provide customers with machines and systems that enable them to produce reliably and at competitive per-piece costs in their day-to-day operations. The company based in Nürtingen meets these requirements with integrated manufacturing solutions that are suitable for a wide range of industries. “We are successfully transferring the high demands of the automotive industry to other exciting sectors,” says HELLER CEO Dr Thorsten Schmidt. This is also reflected in the distribution of HELLER’s order intake in the first half of 2023 according to industries and workpieces. Schmidt explains: “42 percent of our order intake come from general mechanical engineering, power engineering, aerospace and tool and mould making, among others. The truck and agricultural sector accounts for 29 percent of new orders, while passenger cars still account for three percent. Non-combustion engine-related orders for heavy-duty and light-duty vehicles accounted for 26 percent of the total. Our aim is to expand into even more industries – and EMO offers us a great opportunity to do so.”

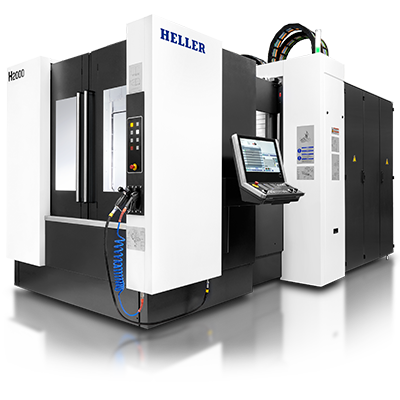

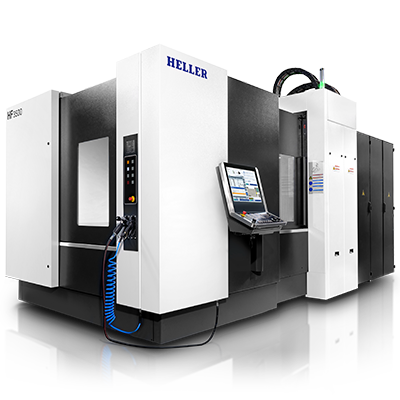

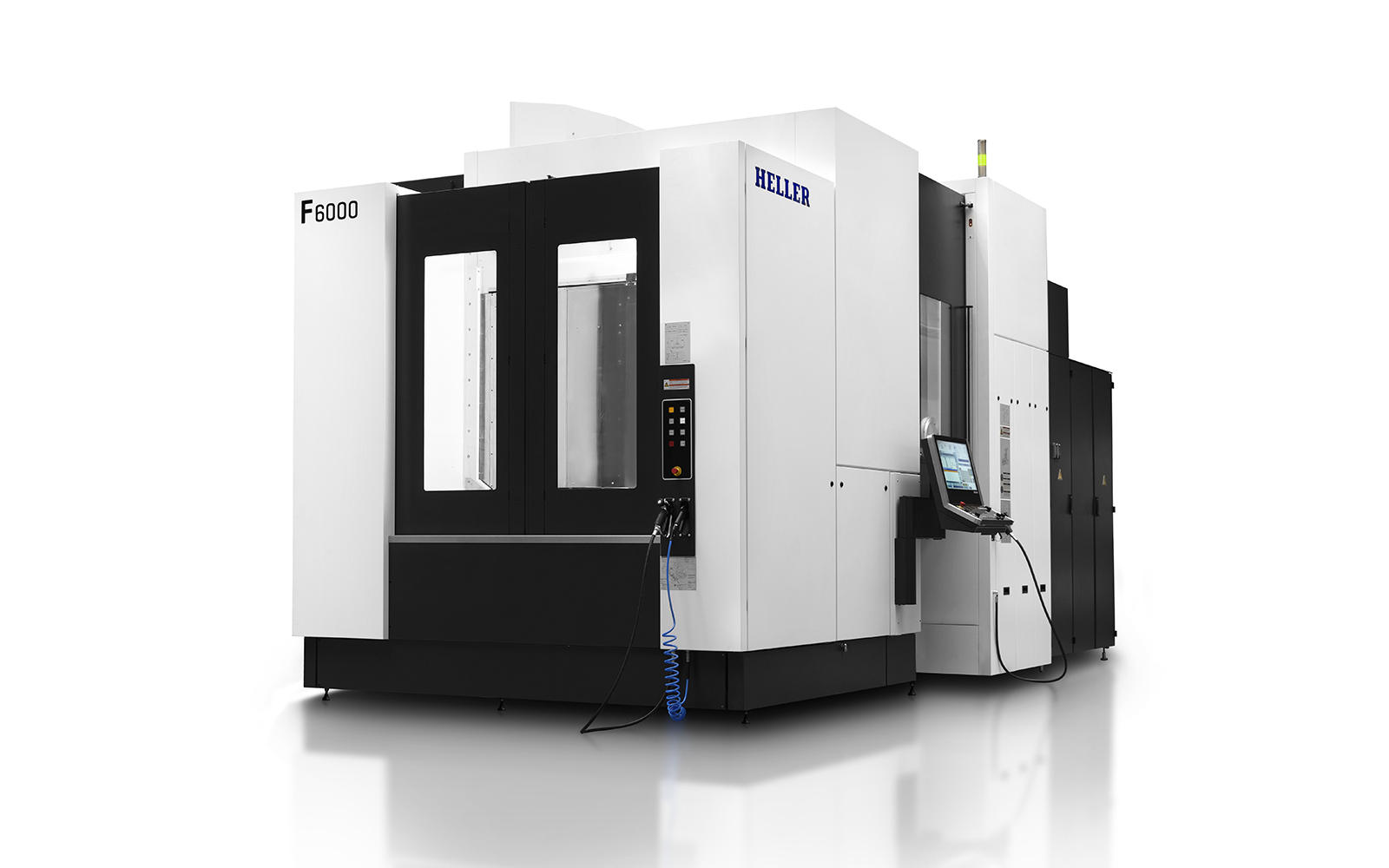

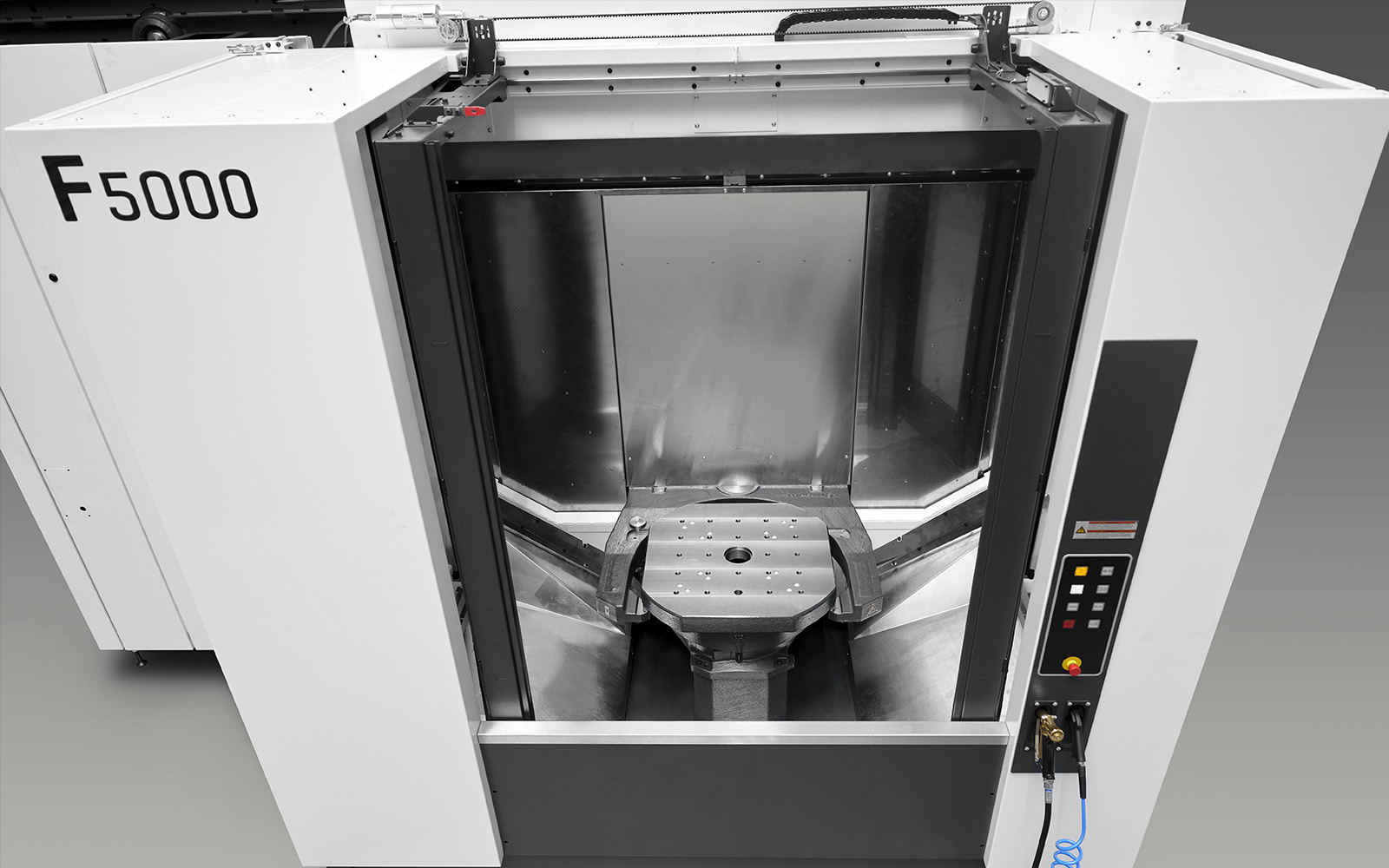

5-axis machining centre F 6000 – Designed for Production

The 5-axis machine with head kinematics is designed from the ground up for flexible, powerful series production. Like all HELLER machines, it sets a benchmark for cutting performance and precision. Highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. The F 6000 also boasts first-class equipment, a small footprint with a width of 3.70 m and expandability with technologies such as Mill-Turn, interpolation turning or power skiving. Dr Manuel Gerst, Head of Development of the HELLER Group, adds: “With the F 6000, we have succeeded in raising the already high standard to a new level. This is also thanks to newly developed key components ‘Made by HELLER’. These include the completely redesigned swivel heads including the integrated motor spindles specially developed by HELLER. The Speed Cutting Unit (SCU) in combination with the HSK-A 100 tool shank reaches speeds of 15,000 rpm. As an alternative, HELLER offers the Dynamic Cutting Unit (DCU) designed for universal use with 380 Nm and 12,000 rpm. For heavy-duty machining, the Power Cutting Unit (PCU) with a gear spindle and 1,150 Nm is still available.”

For combined milling and turning operations, the machine is equipped with the optional Mill-Turn function, in which the high-torque DDT (Direct Drive Turning) rotary table with speeds up to 700 rpm plays a key role. In line with the trend towards complete machining, this eliminates the need for reclamping on separate turning machines. The result is improved workpiece accuracy and significantly reduced cycle times, especially for series products. The pallet changer is included as standard as the first level of automation. The new ‘Automation-ready’ option enables easy integration of the HELLER rotary pallet storage (RSP) and HELLER’s standardised linear magazine solutions at a later date.

Another great strength of the F 6000 is its ease of use. The comfortable main operating unit in console design with 24-inch touch screen, together with other features, ensures that the operator quickly gets to grips with the machine. In addition, the significantly wider door to the work area makes it easier to access the workpiece. New processes can also be set up quickly and safely on the machine with the optional SETUP Assist. The new Siemens SINUMERIK ONE control is available as standard. Existing NC programs from F and C series machines with SINUMERIK 840D sl can be directly and easily transferred by the user.

Automation solutions from HELLER – flexible, value-adding, competitive

On show at EMO will be the HELLER RSP 12H6 rotary pallet storage. With a total of 11 pallet storage locations as standard, the automation solution enables flexible and automated handling of machine pallets and is predestined for series production of small and medium batch sizes. A third level can be added to extend the solution to up to 17 storage locations plus loading station. Augmented Reality will be used on the booth to demonstrate its functionality and expandability.

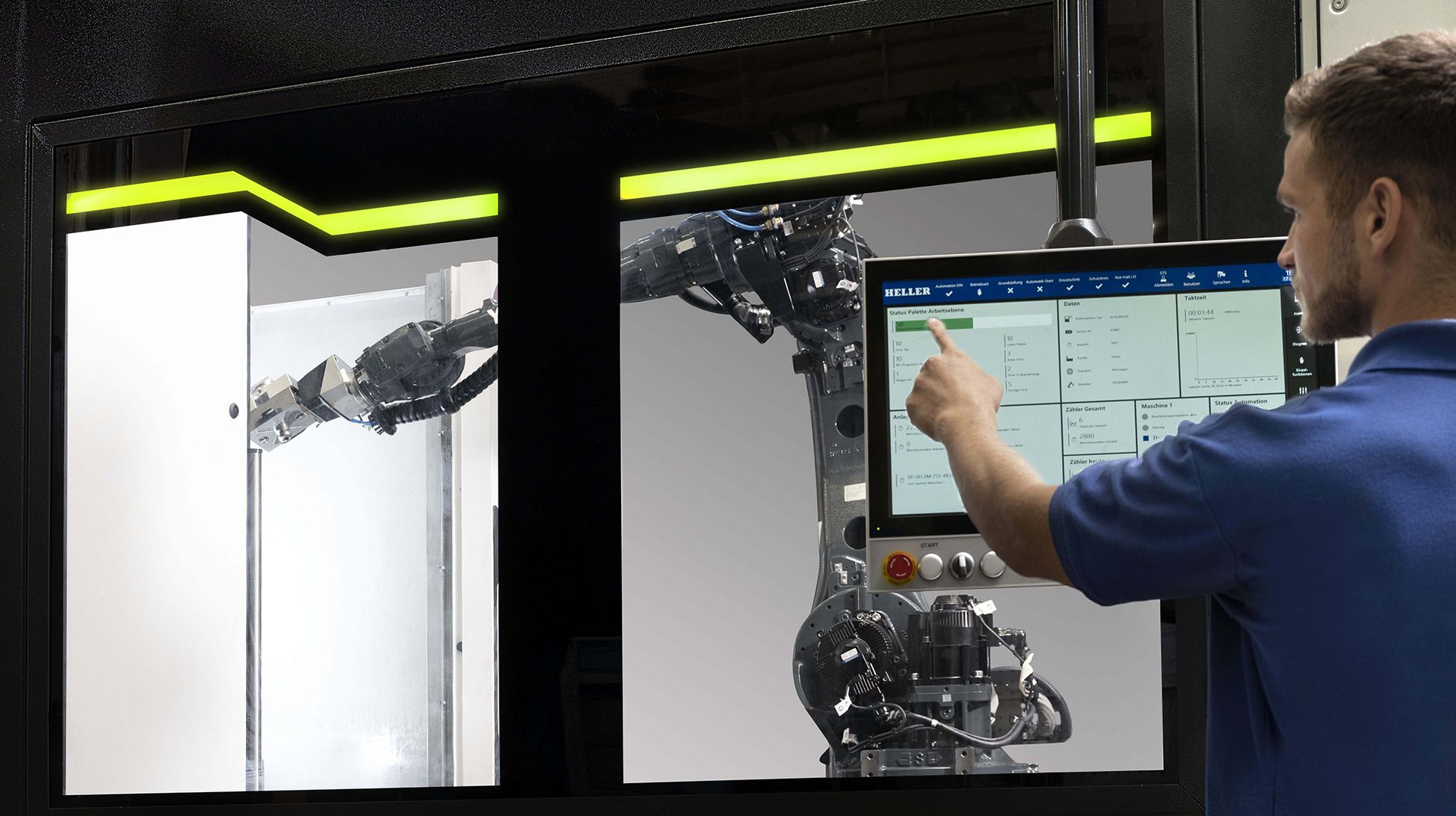

The RZ50 robot cell from the HELLER automation portfolio also provides an insight into flexible robot automation for automatic loading and unloading of workpieces, fixtures and pallets, as well as the automation of other handling tasks.

At the show, HELLER will also be presenting the Automation Calculator. It allows users to enter workpiece data, production information or the desired machine into a touch-enabled terminal and then receive recommendations on the most suitable automation solution and the associated payback time.

Fit for the factory of the future – digitalisation

With a new intuitive operating concept, the HELLER Services Interface ensures transparency in manufacturing, maintenance and service processes throughout the entire lifecycle of the machine. This option can also help reduce machine downtime by providing evaluations and statistics. Visualisation of specific machine status information, including status indicators for axes, spindles or other assemblies, enables users to determine the wear status and take preventive action to reduce unplanned downtime.

The digital twin provides customers with a digital image of their machine. The simulation behaves exactly like the real machine. Its use saves considerable time and money during development, commissioning and optimisation. For example, the use of tested workpiece programs prevents machine damage.

The HELLER HSU motor spindle with face contact check ensures improved production quality in single-part and series production. Contamination in the HSK tool interface is accurately detected – chips as small as 10 μm can be detected both in the taper and on the face contact.

HELLER Services – Lifetime Partnership

With HELLER Full Service Essential, the Nürtingen-based machine tool manufacturer offers its customers an attractive package for complete cost control: for new machines, all maintenance costs are included for a full three years, from service calls to spare and wear parts, as well as annual manufacturer’s maintenance.

HELLER Blue retrofit solutions provide customers with energy efficiency packages that effectively reduce operating costs and minimise unit costs. HELLER Blue Power Save, for example, ensures that auxiliary units such as pneumatics, cooling and lighting are switched off in stages as required. With HELLER Blue Coolant, the energy consumption of the high-pressure coolant pump can be reduced depending on the machining process. HELLER Blue Chill combines a powerful cooling unit with a matching heat exchanger to equip machines for maximum energy efficiency.

From now on, customers in other European countries will also be able to use the myHELLER customer portal to keep track of their entire machine fleet at all times. Spare and wear parts can be ordered quickly and easily – from anywhere, at any time. The portal for German customers was launched only last year.

In addition, HELLER experts are currently working on web-based AI part identification for mobile devices. HELLER Lens is designed to provide customers with even faster and more reliable identification of spare parts.

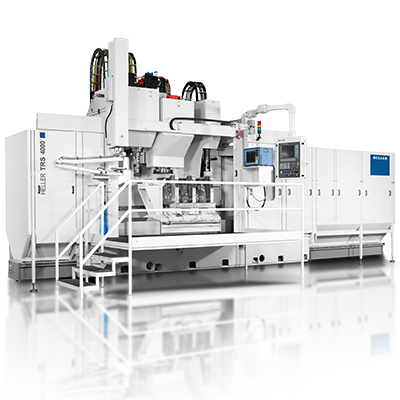

Experience meets innovation – HELLER know-how

One key to higher productivity is complete machining on a single machine. That is why HELLER specialists are in the process of integrating different technologies into the current range of machining centres.

On the F 6000 5-axis machining centre, various turning operations, power skiving gear cutting technology, trochoidal milling, simultaneous 5-axis machining and an external cylindrical grinding operation will be presented as part of a performance and technology demonstration in C45 steel.